Placing an emphasis in the application of computer systems to modern manufacturing.

Hands-on Learning Technology Programs

Classes and Labs Taught by Professors (Not by Teaching Assistants)

>75% of Classes Have Laboratory

Manufacturing engineering technology (MfgET) is a multi-disciplinary field that integrates knowledge from areas of study such as science, math, computers, mechanical engineering, electronics engineering, management and economics. MfgET is a profession that gives you the expertise to develop tools, processes, machines and equipment to make quality products at a reasonable cost. The profession also involves working with and coordination of people from several other fields. In addition to providing a strong background in the fundamentals of manufacturing engineering technology, the program places an emphasis in the application of computer systems to modern manufacturing. This includes topics such as robotics, computer-aided design (CAD), programmable logic controllers (PLC), and computer-aided manufacturing (CAM).

The Manufacturing Engineering Technology program is a full four-year BS degree. Although it is not as mathematically rigorous as the Mechanical Engineering program, it does share a few courses with it and is quite rigorous compared to other many similarly titled programs elsewhere. Students in the Manufacturing Engineering Technology program have the opportunity to use their technical electives to obtain a minor in Robotics Technology, and graduates have excellent job prospects.

The Manufacturing Engineering Technology bachelor’s of science degree is an ABET-accredited program that integrates knowledge from areas of study such as science, math, computers, mechanical engineering, electrical engineering, management and economics with an emphasis on preparing you to solve real-world engineering problems. It is a profession that gives you expertise to develop tools, processes, machines and equipment to make quality products at a reasonable cost. The profession also involves working with and coordination of people from several other fields.

Students participate in a senior year experience which includes one of the following:

Our students participate in a senior-year experience which includes one team project or a research team project.Six engineering students were recognized this past year at two competitions held at professional conferences when it presented “Mobile Robotics Workcell – Using Robotics to Lure Young Minds to Manufacturing Engineering.”

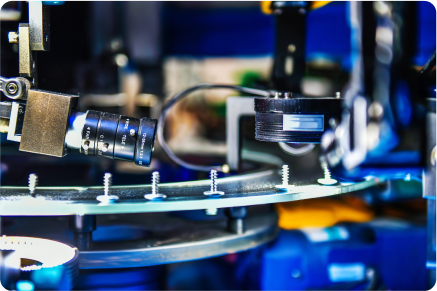

Under the direction of Prof. Jim Devaprasad, the senior project team Automated Promotional Engineering Systems (APES) designed and built a mobile robotics workcell that showcases various automation technologies.

The Bachelor of Science, Manufacturing Engineering Technology, degree program is accredited by the Technology Accreditation Commission of ABET, 111 Market Place, Suite 1050, Baltimore, MD 21202-4012 – telephone: (410) 347-7700.

The path to becoming an electrical engineer is challenging but very rewarding. It involves completing a four-year curriculum that is filled with challenging classes in mathematics, the physical sciences, and, of course, engineering. At LSSU we strive to equip our students and to provide a learning environment that maximizes success in both their studies and future careers.

The Manufacturing Engineering Technology bachelor’s degree program is accredited by the Engineering Technology Accreditation Commission of ABET, http://www.abet.org

Students begin working with 3-dimensional computer-aided design software (CAD) in their first semester. Later in the curriculum they will use the software for computer-aided manufacturing (CAM) and animation.

The Manufacturing Processes Laboratory has facilities where students learn to create mechanical parts, processes for production planning and fabrication (above).

Whether it be a single gear or a complete automobile engine, the complete set of events that results in a finished product is planned and implemented by a manufacturing engineer. Once you graduate from LSSU, you will have many manufacturing career choices ranging from applied technical research to management of systems and personnel. Typical graduates have obtained engineering and technology positions in design of automated manufacturing systems, computer-aided design and manufacturing, quality control, robotics applications, automotive component manufacturing, design of manufacturing processes and equipment, maintenance, sales and management of manufacturing systems. Some graduates have also transferred to graduate schools to pursue master’s and doctoral degrees.

Recent graduates of the Manufacturing Engineering Technology program have worked for Gentex, Precision Edge, Applied Manufacturing Technologies, JR Automation, and Michigan Rod, to name a few.

Technical Areas

Industries